HOW TO READ YOUR TIRE SIZE… If your tire size has two sets of numbers (6-12, 5.00-15, 11.2-24…) the first number (5.00-15) is the approximate width in inches; the second number (5.00-15) is the rim diameter.

If your tire size has three sets of numbers (15x6.00-6, 26x12.00-12, 31x15.50-15) the first number (26x12.00-12) is the approximate height, the second number (26x12.00-12) is the approximate width, and the third number (26x12.00-12) is the rim diameter.

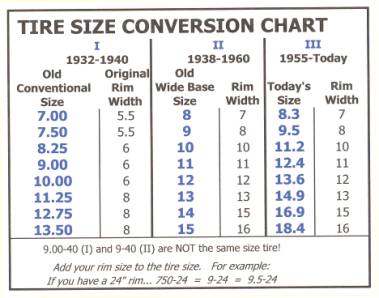

REAR TRACTOR TIRE CONVERSION…

OLD SIZE/NEW SIZE

I t has been years since tire manufacturers changed the numbering system on rear tractor tires. For those who have the older tires on your antique tractors, the change to the new system can be confusing.

t has been years since tire manufacturers changed the numbering system on rear tractor tires. For those who have the older tires on your antique tractors, the change to the new system can be confusing.

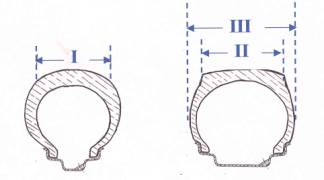

When rubber tires were first used on tractors (1932-1938), the widest rear rim produced was 8”. With larger tires, the sidewalls were pulled in, causing the tire to be very rounded.

The first tire sizes (I) were the approximate tread width measured to the closest one-fourth inch.

In 1938, wider rims were used for better tire performance. With wider rims the tire beads were not pulled in as far, which allowed the tread to flatten and with a deeper tread the tires became more efficient. With the wider rim the same size tire has a wider tread width.

The second sizes (II) still used the approximate tread width. This method measured to the closest inch with no decimal points.

In the mid-50’s, the third number (III) method began. The new numbers referred to the overall width of the tire (sidewall to sidewall). This method measured to the closest tenth of an inch. The tires basically still had the same overall diameter and width as method (II), but a new number size.

FAQ

Q. Can I use the new tire sizes (III) on my old narrow rims?

Q. Can I use the new tire sizes (III) on my old narrow rims?

A. Yes, if you are restoring your tractor for show. The tire beads will be pulled in and make your tire look more rounded and balloon-like, resembling the old tire (I) look. We recommend wider rims for farming or tractor pulling.

Q. Why don’t my new tires (III) look like the tire beads fit correctly when mounted on my old rims (I)?

A. The early rim, produced before 1940, had a 1.4” flange height while today’s rim has a 1” flange height. Using new tires on old rims was not a problem until the 1980’s when tire makers started building tires with beads that fit over the lip (flange) of the rim. Those tires will work on the old rims, but will not look right. On some tires the higher flange covers part of the wording on the sidewall. You have three choices...

- 1. Use tires the way they are even though you don’t like the look

- 2. Use tires with old style beads, such as BKT and Speedways (U.S. tires have new style beads)

- 3. Change to new style rims IF available

Q. How wide should my rims be for tractor pulling?

A. We recommend a rim that is approximately the same as the sidewall width of your tire. Example: 12.4 on 12”, 14.9 on 14”, 18.4 on 18”. You want to keep your sidewalls as straight as possible. This allows you to use lower air pressure without the sidewalls buckling. Lowering the PSI gives a larger footprint for better traction. When you put tires on rims that are wider than the sidewalls of the tire, the tread will tend to concave and will need higher PSI to keep the tread flat.

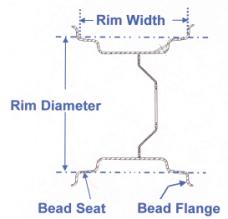

HOW TO MEASURE RIMS AND WHEELS… Rim width is the distance between the bead flanges (inside to inside, not outside to outside). Diameter is measured from the bead seat to bead seat (not outside to outside).

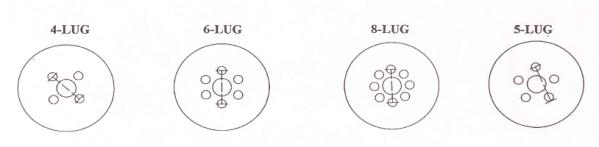

HOW TO MEASURE WHEEL BOLT CIRCLE…When you have an even number of bolt holes…the bolt circle is measured from the center of one bolt hole to the center of the opposite bolt hole (directly opposite of each other as in 12 o’clock to 6 o’clock).

The easiest way to estimate 5-lug bolt circle is to measure center of hole to back of the third hole.

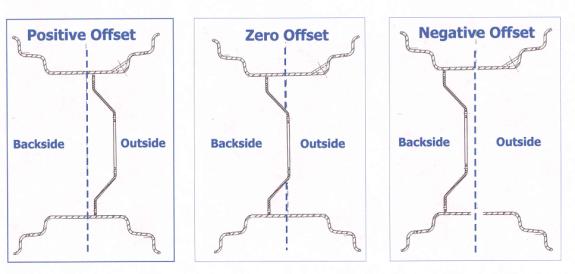

HOW TO MEASURE WHEEL OFFSET… Offset is the distance between the mounting side of the center disc and the rim centerline. Positive offset is when the disc is on the outside of the centerline. Negative offset is when the disc is on the inside of the centerline.

![]()